Description

ABS/PVC Composite Wood Grain Sheet Characteristics and Advantages

- Lightweight Structure

Utilizing ABS engineering plastic substrate with PVC surfacing technology, the sheet density is 35%-40% lower than traditional building materials. Weight per square meter is maintained at 1.8-2.3kg, significantly improving transportation efficiency and reducing installation labor costs. - Superior Impact Resistance

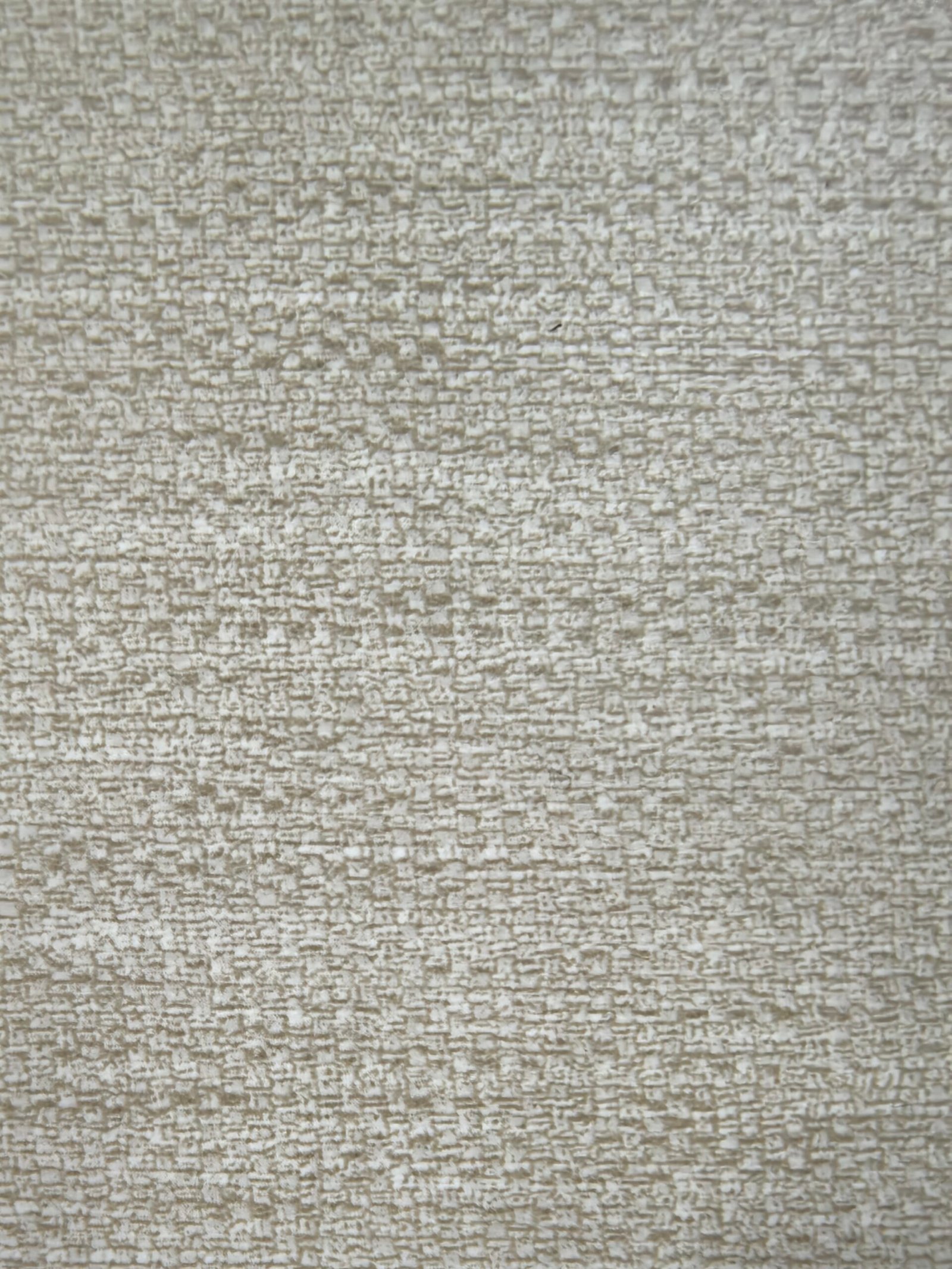

Tested under ISO 6603-2 standards, the ABS substrate layer withstands up to 50J/cm² impact energy, exhibiting 200% higher deformation resistance compared to standard PVC sheets. Ideal for high-traffic commercial spaces and cold-chain storage environments. - Premium Surface Finishes

• 12 base wood grain patterns achieved through 3D digital printing

• 6 standard color schemes (Oak/Walnut/Maple, etc.) with Pantone® customization

• Optional surface treatments: matte/glossy/embossed (0.5-1.2mm depth) - Enhanced Surface Performance

PVC protective layer tested per ASTM D4060:- Taber abrasion resistance: ≥5,000 cycles (CS-10 wheel, 1kg load)

- Stain resistance: Class 5 per GB/T 3810.14-2016 (China National Standard)

- Chemical resistance: withstands pH3-11 solutions

- Long-Term Weathering Assurance

Verified by QUV accelerated aging tests:- Color retention: ΔE≤3.0 after 3,000 hours

- Gloss retention: <15% attenuation

- Operational temperature range: -30℃ to 70℃

- Eco-Friendly Alternative

FSC® certified (COC-123456), offering:- 90% reduction in timber consumption vs. solid wood

- 300% improvement in material utilization

- CARB Phase 2 compliance for formaldehyde emissions

Composite Innovation:

Supports multi-material lamination with:

- Functional layers: Antimicrobial film (>99% efficacy), anti-static coating (surface resistance 10⁶-10⁸Ω)

- Decorative foils: Metalized films (0.05-0.2mm), glass fiber reinforcement

- Special substrates: Bamboo fiberboard, aluminum honeycomb panels

Industry Applications:

- Architectural: Wall cladding/ceiling systems/bathroom partitions

- Furniture: Custom cabinets/system furniture/display fixtures

- Industrial Design: 3C product casings/medical equipment panels/NEV interiors

- Commercial Spaces: Retail store systems/hotel decor/office partitions

Customization Services:

Formosa Plastics Group provides end-to-end solutions:

- Dimensional flexibility: Adjustable width (600-1300mm), custom shapes

- Performance upgrades: Optional UV coating/anti-fingerprint treatment/EMI shielding

- Certification support: CE/ROHS/REACH compliance assistance

- Logistics optimization: Scratch-resistant packaging & JIT delivery

Reviews

There are no reviews yet.