Description

1. textured ABS plastic Characteristics and advantages ✅

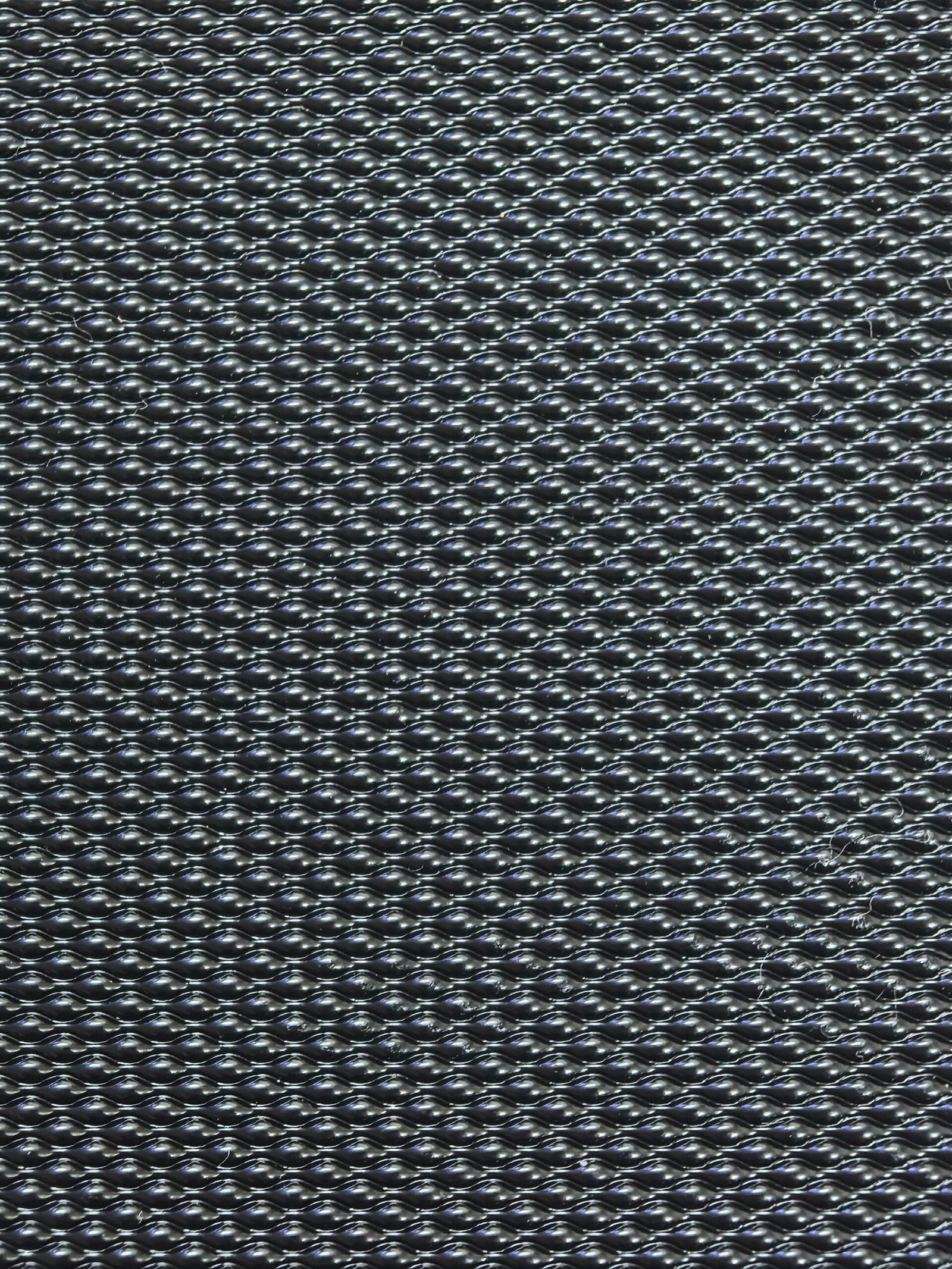

- Diverse surface texture

- Optional texture: frosted, imitation metal drawing, 3D three-dimensional relief, custom LOGO embossing;

- Texture depth 0.1-1.5mm, delicate touch and anti-slip wear。

- ABS sheet performance retention

- Impact strength ≥15 kJ/m² (better than textured PVC board);

- Temperature resistance -30℃ to 90℃, suitable for indoor and outdoor environment.:

- No spraying environmental protection technology

- The mold directly forms the texture, reducing the spraying process and VOC emission;

- textured ABS sheets Comply with RoHS, REACH environmental standards, support recycling.

2.textured ABS sheets Product specification and selection guide 📐

| Argument | Specification range | Application scenario |

|---|---|---|

| Texture type | Frosted/brushed/leather /3D embossed | Silk (electrical panel) Leather (automotive interior) |

| thickness | 0.8mm – 12mm | 1-3mm (decorative veneer) 5-8mm (structural parts) |

| colour | Any color | Metal color replaces electroplating process |

| Surface hardness | R110-R120((Rockwell hardness)) | Scratch resistance is better than ordinary acrylic |

3. industry application cases 🏆

① High-end household appliance

- Refrigerator door panel:Imitation stainless steel brushed ABS texture plate, the cost is 40% lower than metal;

- Air conditioning outlet:Three-dimensional geometric texture to enhance product quality, avoid reflective interference.

② Car interior

- Instrument table decoration strip: carbon fiber texture ABS board, lightweight and high temperature resistance (120℃ short-term)

- Door armrest: leather embossed ABS, soft to touch and easy to clean.

③Commercial space

- Hotel wall decoration board: imitation wood grain ABS instead of solid wood, waterproof and mothproof (suitable humidity ≤85%)

- Showcase veneer: 3D relief texture enhances visual layer and supports backlight transmission.

4. ABS texture board vs. other decorative materials contrast ⚖️

| peculiarity | ABS texture board | Solid wood veneer | Sheet metal | Textured acrylic |

|---|---|---|---|---|

| weight | 1.05-1.20 g/cm³ | 0.6-0.8 g/cm³ | 2.7-7.8 g/cm³ | 1.18 g/cm³ |

| weight | Low (mold one molding) | High (gluing + edge sealing required) | Extremely high (cutting + surface treatment) | Medium (need to be polished to prevent cracking) |

| Weather fastness | Excellent (UV resistant model optional) | Poor (easy deformation and cracking) | Good (but easily oxidized) | aberration |

| Environmental protection property | recyclable | Dependence on forest resources | Recyclable but high energy consumption | Degradation difficulty |

5. Processing and use precautions⚠️

- Mold design:

- Match the depth of etching with the stripping Angle (recommended ≥3°) to avoid mold sticking;

- Texture areas avoid design sharp angles to prevent stress concentration cracking.

- Injection molding process:

- Melt temperature: 220-240℃ (too high resulting in fuzzy texture);

- Holding pressure: 60-80MPa to ensure complete texture filling。

- Postprocessing:

- Avoid using corrosive cleaners (such as acetone) to prevent texture damage;

- The dark texture board is recommended to be waxed regularly to maintain the matte texture.

Reviews

There are no reviews yet.